New research pilot presented at HTHP Symposium 2026

Pelagia’s Head of Sustainability, Food, Ola Flesland, walks to the podium to present a new research pilot with Enerin, Swedish Exergy and SINTEF.

Enerin attended the High-Temperature Heat Pump Symposium last week which was held at the Bella Center in Copenhagen from 21 to 22 January, 2026. Hosted by the Danish Technological Institute (DTI), the event showcases the world’s leading heat pump suppliers able to reach high temperatures for the electrification of industrial heat.

Enerin’s industrial heat pump technology was featured in several presentations and extended abstracts examining ongoing and preliminary research findings from its full-scale pilot projects—GE Healthcare and Pelagia AS, including a new research pilot at Pelagia.

The European collaboration project demonstrating technologies from Circular Energy Systems and Enerin, CircleDRY, was also presented.

The HTHP Symposium is organised by the Danish Technological Institute

The event, held every two years, was organised and opened by Innovation Director, DTI Energy and Climate, Benjamin Zühlsdorf (PhD) from DTI and his team.

Representing Denmark in the International Energy Agency Technology Collaboration Programme on Heat Pumping Technologies (IEA HPT TCP), Zühlsdorf leads the IEA HPT Project 68, which is an independent knowledge hub delivering high-quality insights and information on industrial high-temperature heat pumps.

Essentially the IEA HPT Project 68 provides decision-making support for industry intent on electrifying processes with high-temperature heat pumps. The information contained within the hub is designed for multiple stakeholders targeting net-zero solutions.

Enerin in new research project with Pelagia

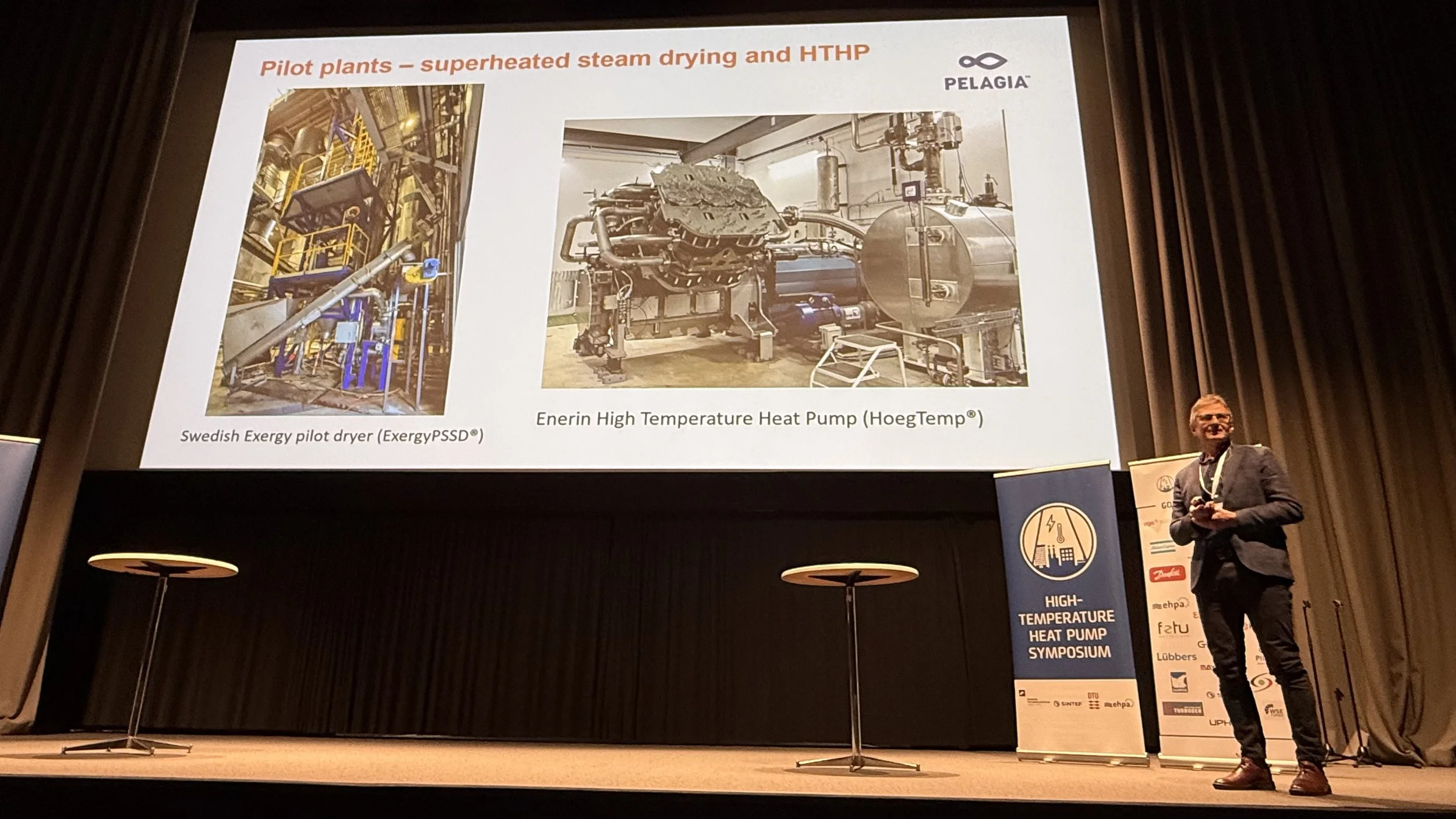

Since March 2025, Enerin has a 400 kW HoegTemp heat pump installed at the Pelagia fishmeal and fish oil facility in Måløy to recover waste heat from its production process. The plant ramps up from cold to full capacity whenever a shipload of fish arrives, to process the leftovers from fillet production.

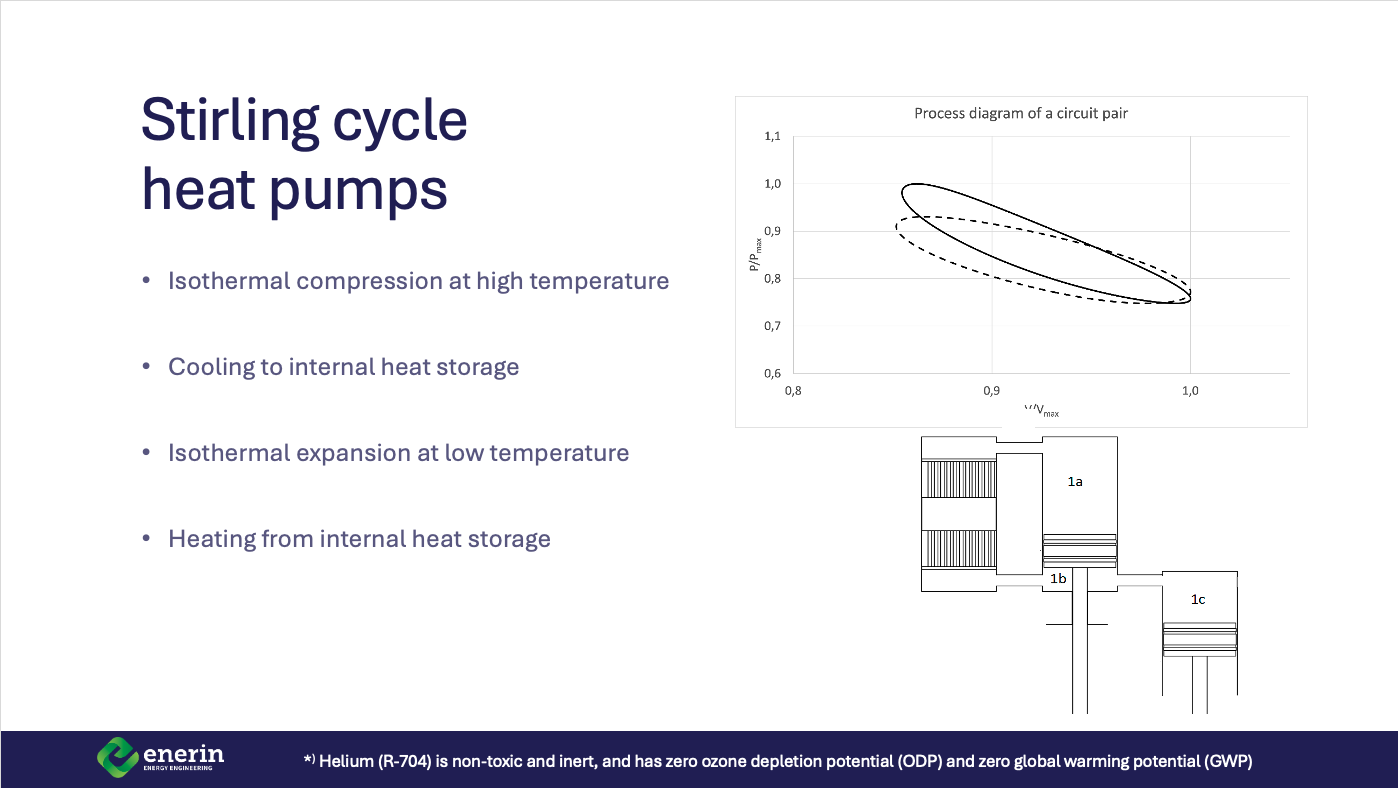

The HoegTemp captures thermal energy from product-contaminated condensate generated during drying and upgrades it to steam, which is fed back into the steam dryer. Source and sink heat are transferred between the stirling process and external water circuits by several compact heat exchangers integrated with the heat pump.

Steam is produced in a steam generator by heat from the sink side external water circuit. The heat pump uses an intermediate water circuit, separated from the contaminated condensate by a plate heat exchanger to avoid fouling of the internal heat exchangers and maintain a steady flow rate independent of condensate flow rate.

A key differentiator of Enerin’s technology is its ability to integrate seamlessly with other industrial energy systems. In this installation, the HoegTemp heat pump operates alongside a cascade of ammonia heat pumps and mechanical vapour recompression (MVR) units within the same machine room.

The ammonia-based system recovers the highest-temperature waste heat and supplies low-pressure steam to the cookers, while the HoegTemp unit upgrades lower-temperature waste heat to high-pressure steam for the steam dryers. This way, the efficiency advantages of both heat pumps are combined optimally. Now, a second pilot is being tested on-site at Pelagia, Måløy, using the HoegTemp industrial heat pump.

Pelagia Product and Process Developer, Ola Flesland, presents pilot project using superheated steam

Pelagia’s Head of Sustainability, Food, Ola Flesland, presented the preliminary findings of the new pilot research project that Enerin is undertaking with Pelagia, Swedish Exergy and SINTEF to test high-temperature drying for fishmeal.

The aim of the project is to combine the HoegTemp industrial heat pump with Swedish Exergy’s superheated steam pilot dryer to achieve the best quality fishmeal products and to address the energy efficiency of the entire product process.

The paper he presented was titled Energy Efficient Fishmeal Drying Using High-Temperature Heat Pumps and Superheated Steam (O. Flesland Pelagia); A. Høeg (Enerin); A. Brækken (SINTEF); P. Verma (Swedish Exergy).

Flesland explained that Pelagia can produce high-quality fishmeal using superheated steam drying as the final drying step in the fishmeal production process. It was preferable, he said, to apply a short drying time of approximately 20 seconds that minimises protein digestibility reduction.

“The protein digestibility is damaged or reduced when a hard heating process is undertaken. We use this as an indirect measure to assess the quality of our fishmeal,” Flesland said.

“The initial drying results reveal a potential 70% reduction in energy consumption for the complete fishmeal production process by combining Enerin’s high-temperature heat pump with Swedish Exergy’s pressurised superheated steam drying.”

“The state of the art is air drying, where the product temperature reaches approximately 70°C. In superheated steam drying, that is drying with pure steam, the product temperature reaches a minimum of 100°C at atmospheric pressure.

In superheated steam drying, where the drying medium consists of pure water vapour, the product temperature is intrinsically linked to the saturation temperature of steam. At atmospheric pressure, this results in minimum product temperatures of around 100 °C, corresponding to the boiling point of water, with higher temperatures achievable as the degree of superheating increases.

Enerin’s HoegTemp can be set up for any desired temperature glide—from a small glide for steam generation to a high glide for the heating of air or fryer oil. It can utilise low-glide sources such as condensation heat, or high-glide sources such as humid air.

The HoegTemp is recognised for its leading efficiency by delivering process heat at high temperatures. It is able to achieve a one step, large temperature lift, where it can ramp-up heat at a rapid speed, with no condensing and boiling of refrigerants.

Arne Høeg presents Enerin’s GE Healthcare pilot

Arne Høeg presenting the GE Healthcare use case at the HTHP Symposium 2026. Picture courtesy of Cordin Arpagaus.

At the GE Healthcare contrast media production facility in Lindesnes, Norway, Enerin has its second full-scale pilot project installed from a total of three pilot projects in Norway.

Enerin CEO Arne Høeg presented a paper titled Steam generating heat pump at pharmaceutical plant (A. Høeg (Enerin); K. Løver (Enerin); I. Fløystøl (GE Healthcare) which has clocked a running time of 4,000 hours. Housed in a container on site, the 400kW HoegTemp heat pump from Enerin supplies both steam and cooling for the chemical distillation processes.

The heat pump extracts low-grade heat from the cooling circuit at temperatures between 15°C and 38°C and upgrades it to 2-bar process steam at approximately 135°C.

This temperature lift places the HoegTemp® heat pump among a small group of industrial systems capable of replacing fossil-based steam, achieving a Carnot efficiency of up to 51%.

Circle Dry was presented by Jari Bendsen from Circular Energy Systems

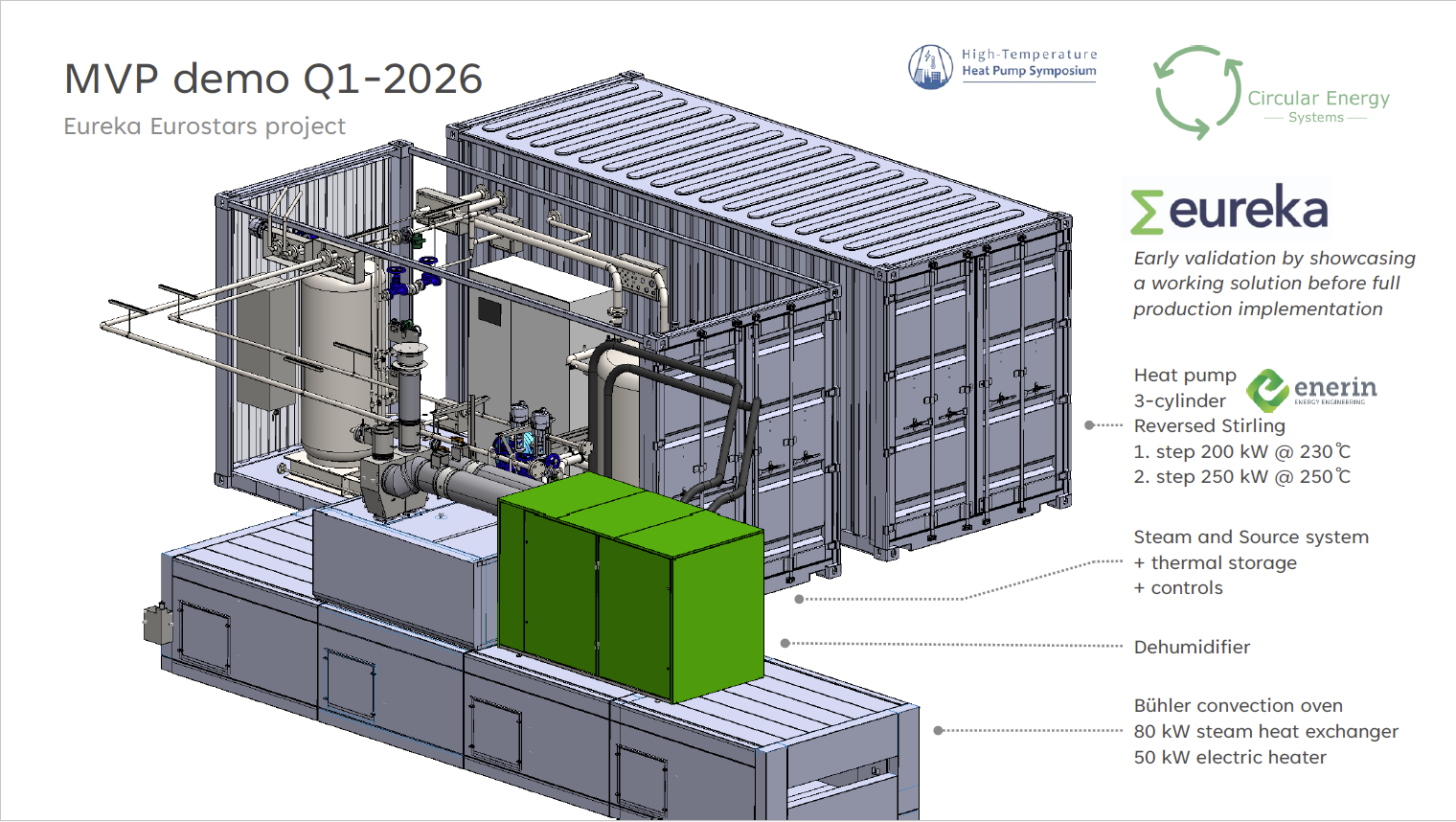

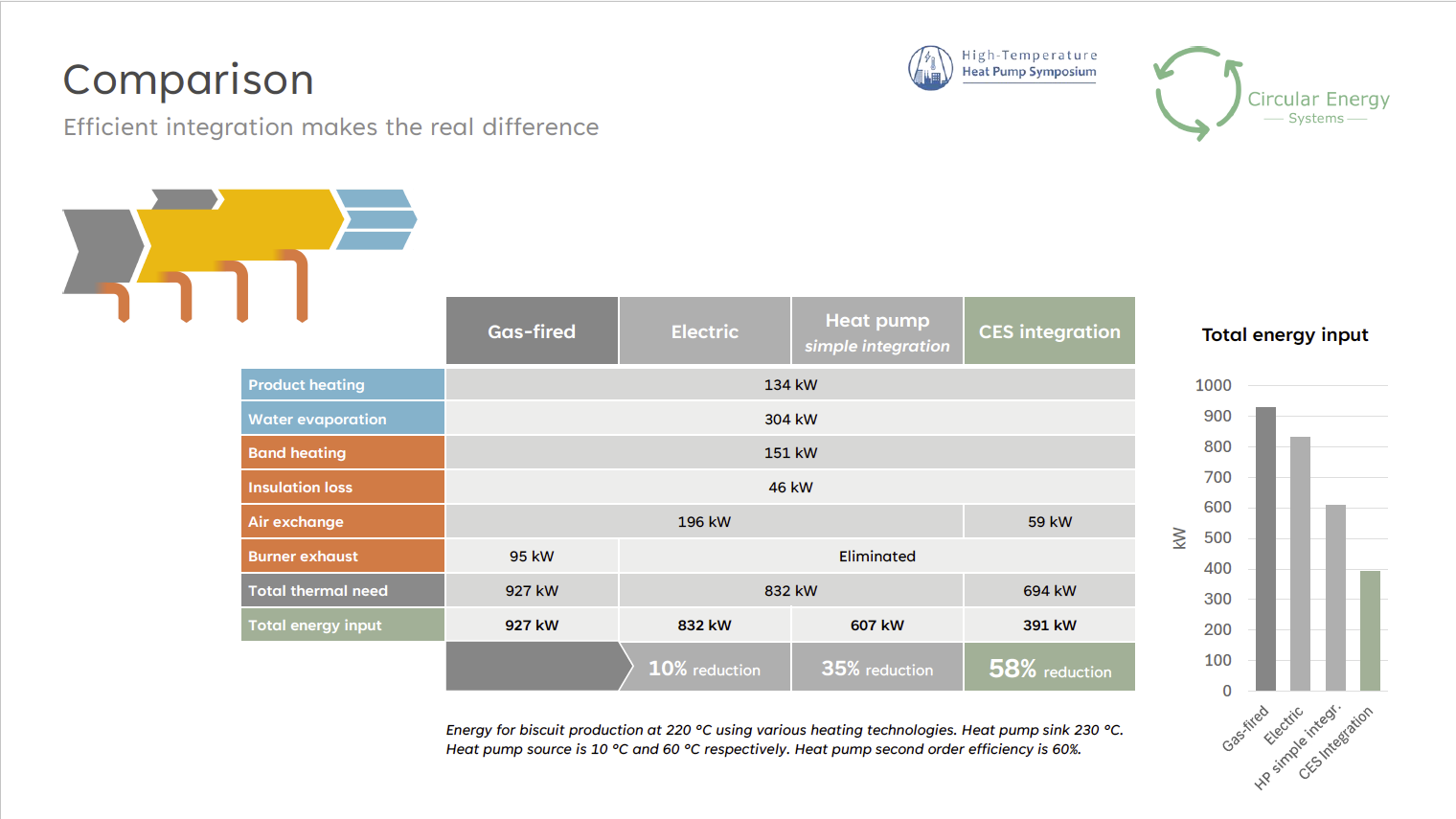

Circular Energy Systems (CES) and Enerin have partnered to develop the 250 kilowatt (kW) thermal power retrofittable drying system called CircleDRY coupled with a HoegTemp high temperature heat pump (HTHP).

CircleDRY aims to facilitate the industrial transition to electric drying with increased energy and resource efficiency, and less carbon dioxide (CO2) emissions. The project, funded by the European Union, Eureka and Eurostars, was presented by CES Founder, Jari Bendsen, below.

News on this project can be read HERE: